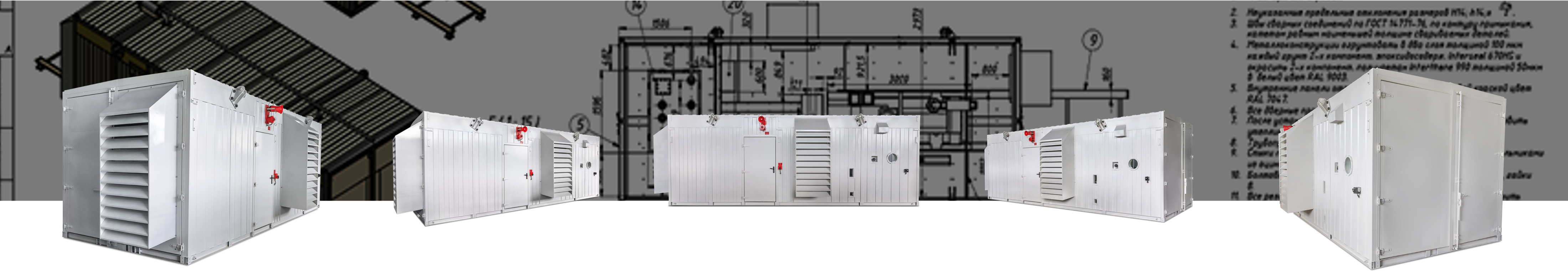

Design Bureau Avantgarde develops and manufactures technologically fully welded, block-modular buildings based on the individual project of the customer.

The production of such systems is a complex technological process and requires the presence of highly qualified specialists ready to solve any tasks.

The development and manufacturing of technological complexes require strict adherence to all norms and industry standards, ensuring high product quality. All stages of work consider the analysis of the customer's technical assignment. The project development takes into account maintenance features and further safe operation. The design process considers all necessary parameters, including guaranteed power supply systems, emergency lighting, ventilation and air conditioning, as well as autonomous operation and fire extinguishing systems. Each unit undergoes comprehensive testing after assembly to check the functionality of all systems and components. All process stages are meticulously documented, and the complexes undergo necessary certification procedures. The high-quality standard is achieved through a comprehensive approach, the use of high-tech equipment, the high qualification of specialists, and strict compliance with customer requirements.

Developing project documentation using applied solutions such as Autodesk and SolidWorks, as well as other specialized programs, represents a modern and efficient approach to design. They provide developers with powerful tools for creating and analyzing projects.

The use of 3D models in design offers several important advantages. Firstly, it provides a more visual representation of the project, making it more understandable for all participants. Secondly, 3D models allow for a more detailed examination of the project, identifying potential problems and improving its parameters. Moreover, it facilitates faster and more efficient collaboration within the team and with clients.

Prototyping non-standard solutions and parts is an important stage in the development process. It allows for testing new ideas, identifying and addressing weaknesses, and optimizing the project. This approach contributes to improving the quality of the final product.

The combination of modern software solutions, 3D modelling, and prototyping creates a more efficient and quality design process. This method helps save time, reduce risks, and achieve better results in project development.

Understanding the breadth of application for such engineering solutions is very important, as it depends on the unique requirements of each customer. Primarily, these developments find their application in industries such as the oil and gas sector, energy, mining, and agriculture.

An important advantage of such engineering solutions is their mobility and autonomy. These qualities attract the aforementioned companies because they allow for a rapid response to changing conditions and the relocation of equipment to necessary points. Autonomy, in turn, ensures reliable operation even in remote or inaccessible locations where access to the main infrastructure may be limited.

These engineering solutions provide companies with effective means for reliable operation in conditions requiring a high degree of mobility and autonomy. They allow for the optimization of production processes and offer flexibility in quickly adapting to changing conditions directly at the workplace.

Our company adheres to high European standards and requirements in the processes of designing and manufacturing equipment. Our production facilities are equipped with advanced tools from leading global manufacturers.

In our production, we use components and products from leading global brands such as Schneider Electric, ABB, DKC, Meanwell, Atlas Copco, and others. Our company's specialists regularly undergo advanced training courses, allowing us to maintain the highest quality level at each stage of the production process. This approach enables us to provide our clients with products that meet the highest standards of reliability and efficiency.